TODAY’S PATENT – STANDING WAVE PIPELINE CLEANING METHOD

The STANDING WAVE PIPELINE CLEANING METHOD was invented by Leo R Newfarmer on the 8th of September 1970, bearing patent number US3527611A.

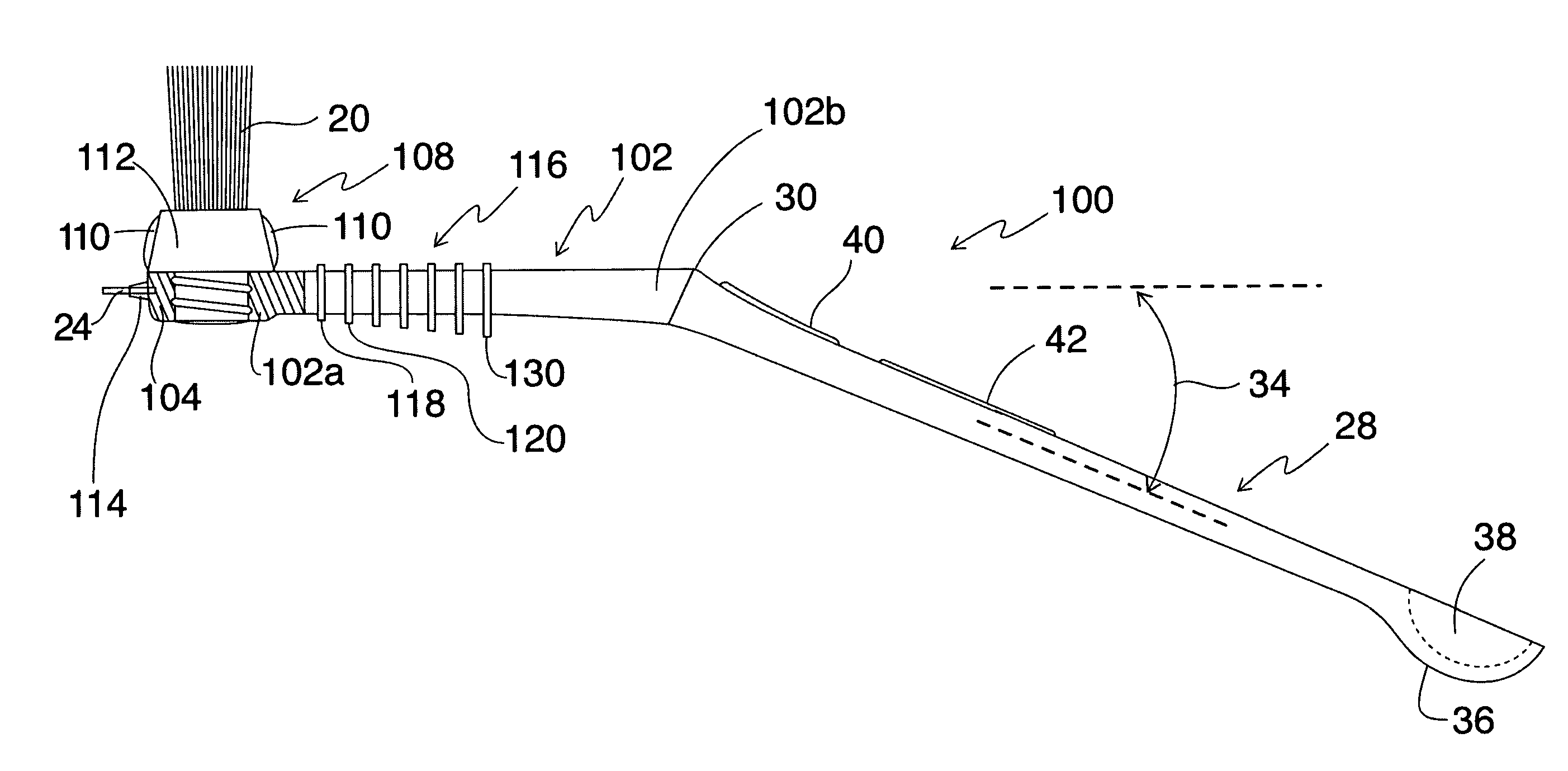

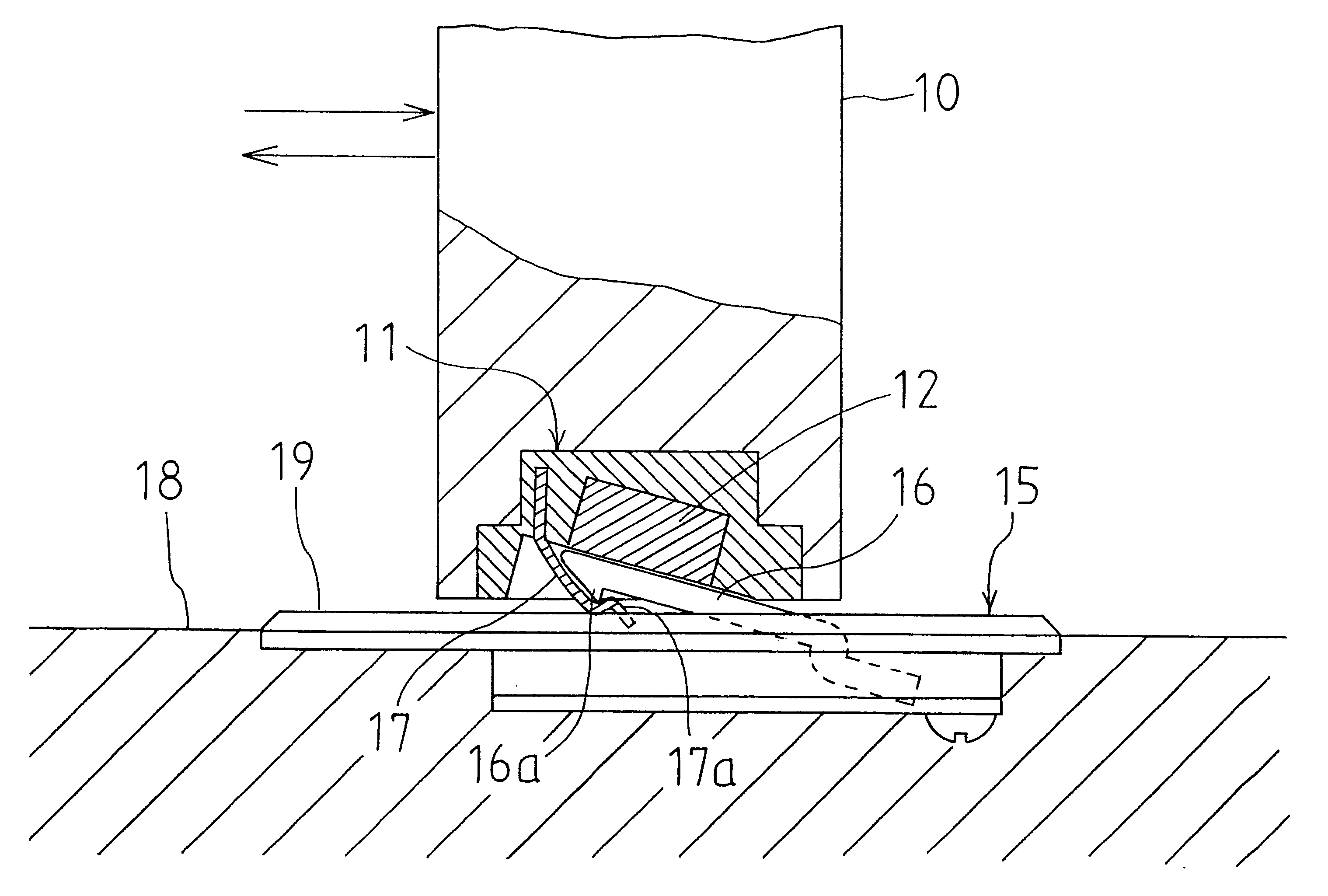

This present invention generally relates to a method of cleaning and descaling pipe wherein abrasive collar means is positioned about the pipe and in intimate contact with the outer surface thereof. Longitudinal standing wave vibrations are generated in the pipe, causing movement of said abrasive collar means relative to said pipe. The present invention relates to pipeline-laying operations, and more particularly to a method of cleaning and scouring the outer surface of pipe to prepare for coating with anti-corrosion substances prior to burial of the pipe in the ground. Transportation by pipeline is a major and growing industry. With the use thereof formerly confined almost entirely to movement of water, gas and petroleum products, pipelines, with the advent of slurry transport, have become useful for long and short hauls of a wide variety of raw materials and finished products.

Improvements in pipeline construction techniques which tend to speed installation thereof, reduce pipeline costs and result in a longer useful pipeline life, are therefore of great economic importance. The outer surface of metal line pipe, even new pipe, is always to some extent covered with so-called mill scale–grease and dirt which must be removed immediately prior to application of the protective covering or coating commonly used in the pipeline art to exclude water, air and other corrosive agents present in the ground from the pipe. One prior art expedient for removing mill scale to expose a dry, clean metal surface suitable for bonding by a protective coating is the use of machine-driven wire brushes propelled in rotary fashion about the pipe. Most commonly, such brushes are associated with an assembly which moves slowly along the line as a self-propelled vehicle a short distance ahead of the .machines applying the protective outer coating.

-150x150.jpg)

+1 888 890 6411

+1 888 890 6411