TODAY’S PATENT – WELDING HELMET CONFIGURATION PROVIDING REAL-TIME FUME EXPOSURE WARNING CAPABILITY

Invented jointly by Douglas N. Dunbar, Bruce John Chantry, Badri K. Narayanan, Steven R. Sumner and William T. Matthews and currently assigned to Lincoln Global Inc. The application was granted patent in 2019 and the same was published on 15-10-2019 by the USPTO. The innovation introduces a significant advancement in welding safety through the incorporation of welding helmets that integrate real-time fume exposure monitoring and warning capabilities during arc welding processes. This solution addresses the critical concern of protecting welders from potentially harmful fumes and particulates generated during welding operations. By providing real-time exposure information and alerts, it serves as a vital risk management tool during welding processes.

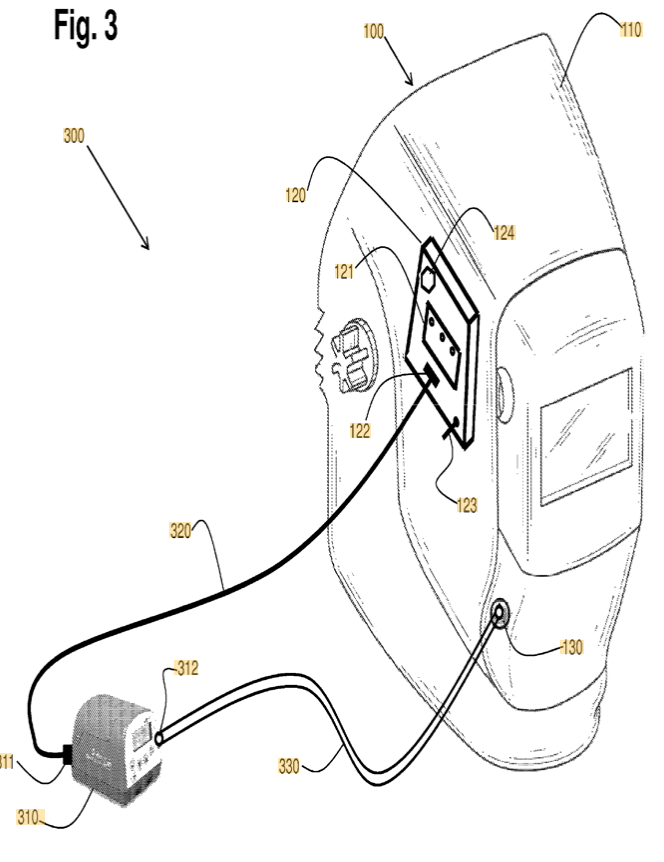

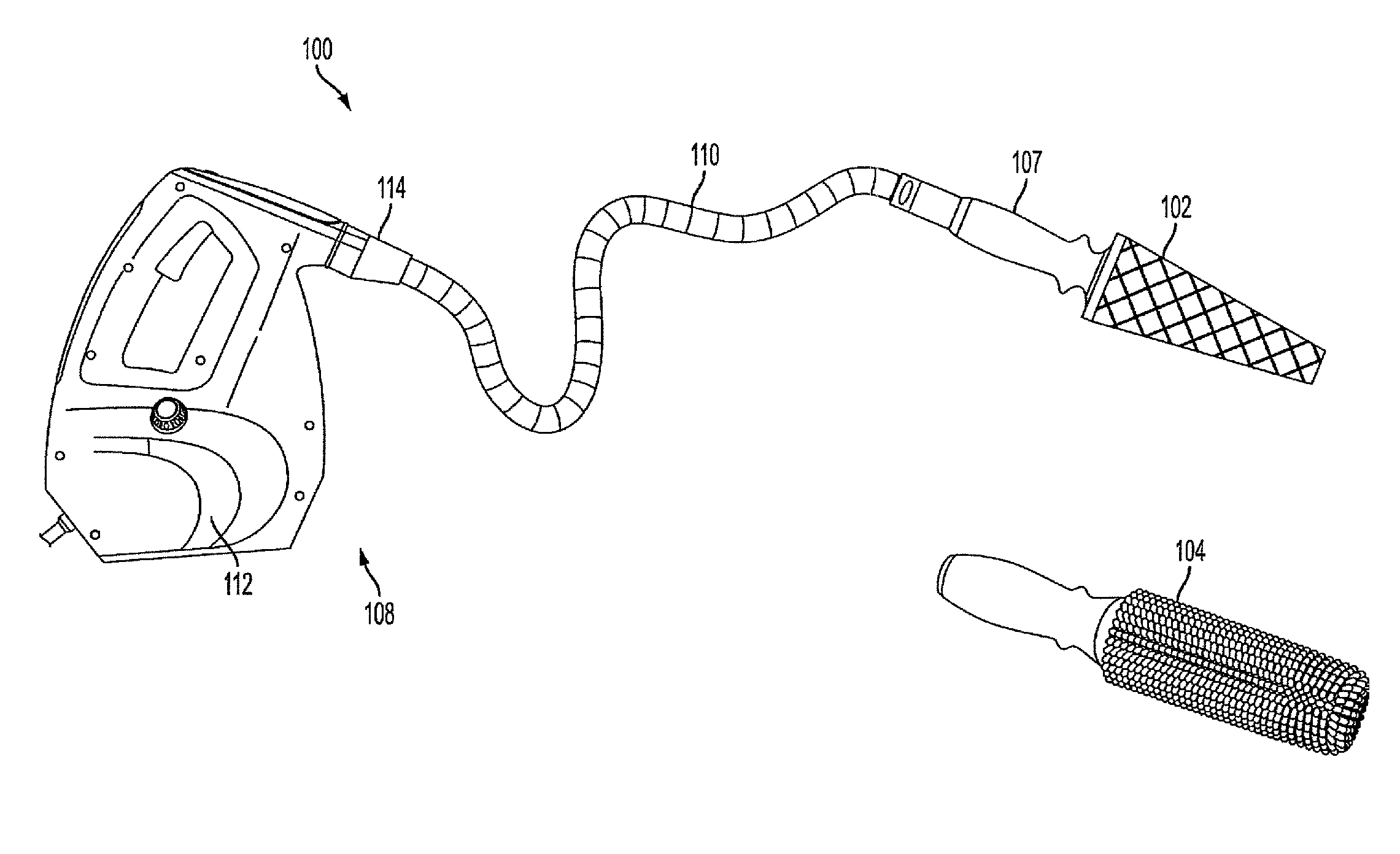

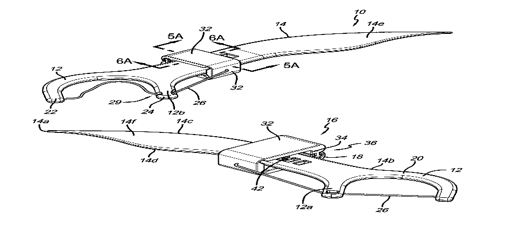

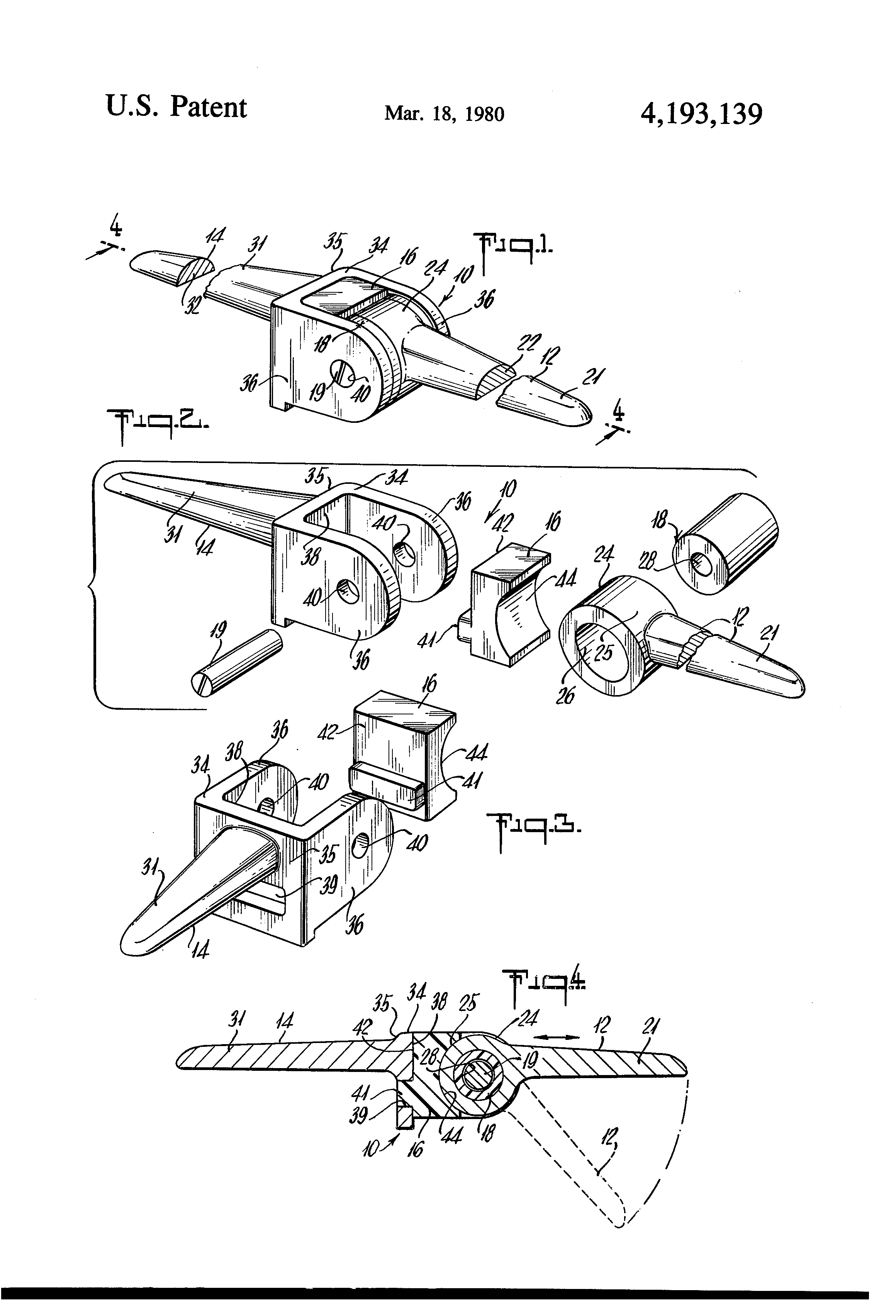

The helmet is not only constructed to safeguard the user’s head during welding activities, but it also features an intelligent warning apparatus and an air-sampling pick-up and output port. The air-sampling pick-up and output port are strategically positioned within the helmet to facilitate the collection of breathable air. This air is then directed through an air sampling tube, which extends from the helmet to an external aerosol monitoring device which plays a pivotal role in assessing the air quality within the helmet in real-time.

Crucially, the intelligent warning apparatus within the helmet is connected to this aerosol monitoring device. This connection allows the warning apparatus to receive and analyze the air sample output data generated by the aerosol monitoring device. By processing this data, the warning apparatus can accurately evaluate the levels of potentially harmful fumes and particulates present within the welding environment.

+1 888 890 6411

+1 888 890 6411