TODAY’S PATENT – METHOD FOR MANUFACTURING LIGHT EMITTING DEVICE

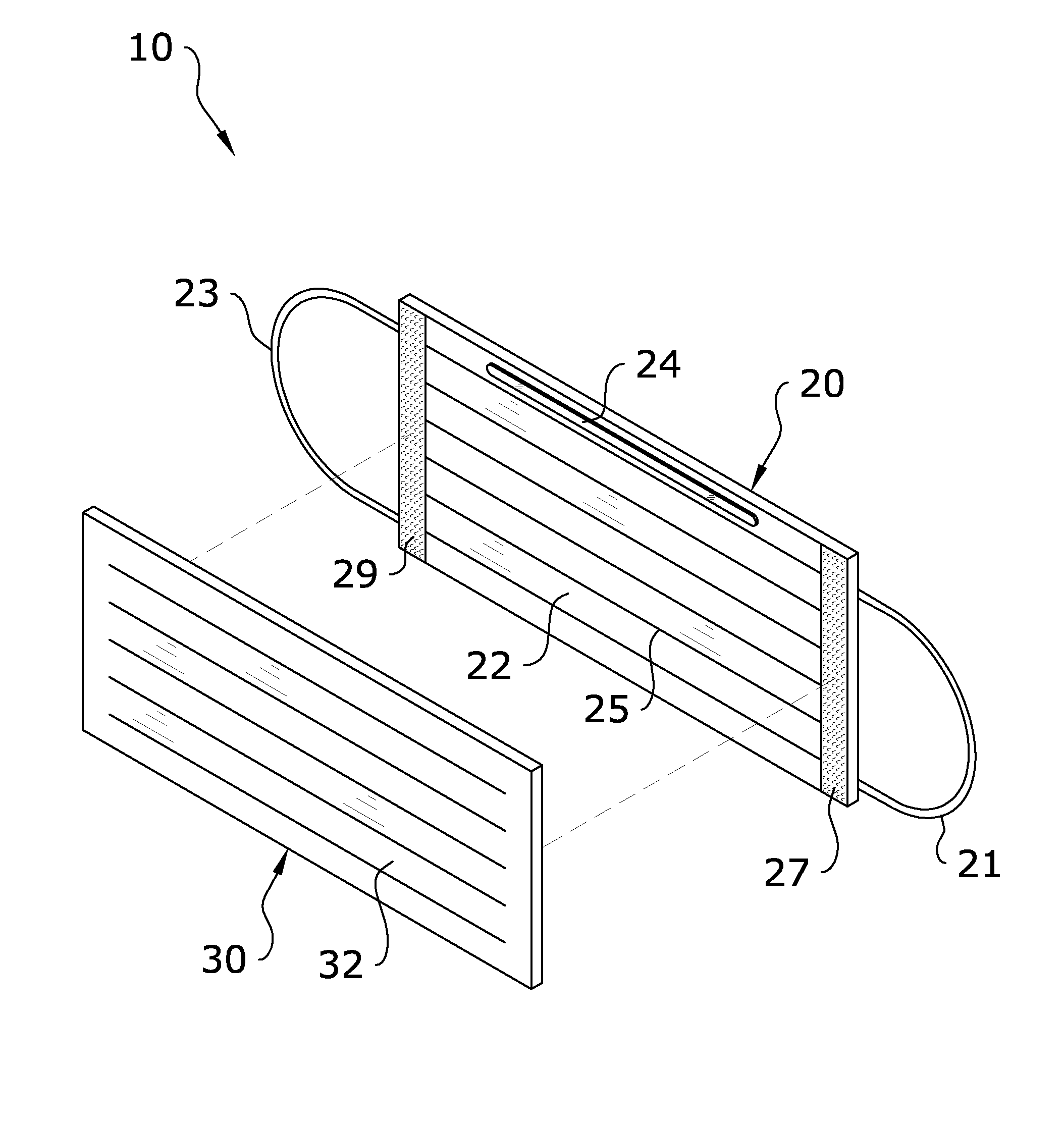

This invention relates to a method for efficiently and accurately cutting a wafer that contains a III-V group compound semiconductor layer and is used to manufacture light-emitting elements. The wafer consists of an n-type semiconductor layer 17a, a p-type semiconductor layer 17b, and a substrate 1 with a thickness of 50 μm to 200 μm. The cutting process follows a predetermined line to achieve precise cuts. The Japan Patent Office granted this invention a patent on July 11th, 2012, with the serial number JP4970628B1.

The III-V compound semiconductor is challenging to cut due to its high hardness and strong crystal anisotropy. Additionally, substrates made of high-hardness materials such as sapphire are often used to stack III-V compound semiconductors, making the cutting process even more difficult. This invention aims to solve these issues by providing a method for cutting III-V compound semiconductor wafers with ease and precision. With this new method, manufacturing of light-emitting elements using III-V group compound semiconductors can be done more efficiently, cost-effectively, and accurately.

+1 888 890 6411

+1 888 890 6411